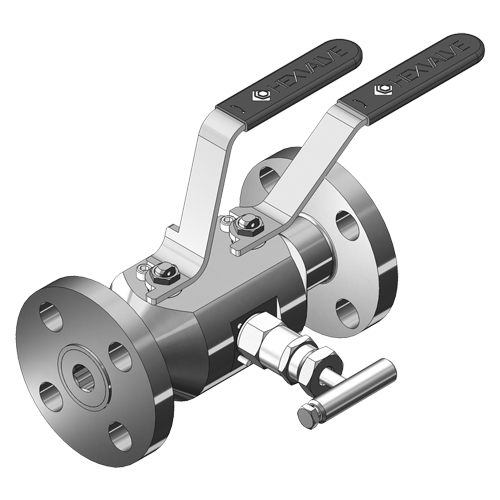

Hexblok Modular Series

Double Block & Bleed Valves

Hexbloks are used primarily on upstream offshore/onshore oil production and initial processing installations. Typically used on liquid hydrocarbon applications to minimize the size and weight of the pipe-valve assemblies associated with gauge pressure or analytical instrumentation. Used specifically for primary and/or secondary isolation, vent and calibration access, or sampling or injection applications.

Also used in downstream oil refining and petrochemical production on flanged process piping.

- Overall length reduced by 70%

- Overall weight reduced by 80%

- Reduced labor costs

- Reduced leak points

- Brings pressure point closer to pressure measurement

- Adjustable, live loaded Teflon or Grafoil packing on ball valves insures zero external leakage

- Single and double flanged versions available along with NPT by NPT

- Large variety of standard and optional forged or bar materials and outlet options, means you can select the style and material you need immediately from the catalog

- Special built-to-order design inquires welcome

Sizes: 1/2″ through 2″; 10, 15, 20, 24 mm orifice sizes

Working pressure: in accordance to ASME B16.5 for class 150 to 2500 up to 5k

Working temperatures: 450°F (232°C) for Teflon packing and PEEK seas and graphite packing (fire safe)

- API 607 5th Edition (Fire Test)

- ASME VIII (pressure boundaries)

- PED

- ANSI B16.5 (flange dimensions)

- EN10204.3.1 (material traceability)